In the iron & steel industry, fresh water is generally used for processes and cooling, while seawater is generally used after pretreatment for single-pass cooling systems.

Water recovery in the steel sector involves cooling and desalinating water to control salt concentration in circulation systems, and decreasing consumption and discharge of fresh water while improving steel quality and the service life of equipment.

Combining clarifier, reverse osmosis, and ultrafiltration can deliver high contaminant removal and reusable effluent water.

High-quality effluent is easier on the equipment, eco-friendly, and more economically feasible than discharging water untreated into the environment.

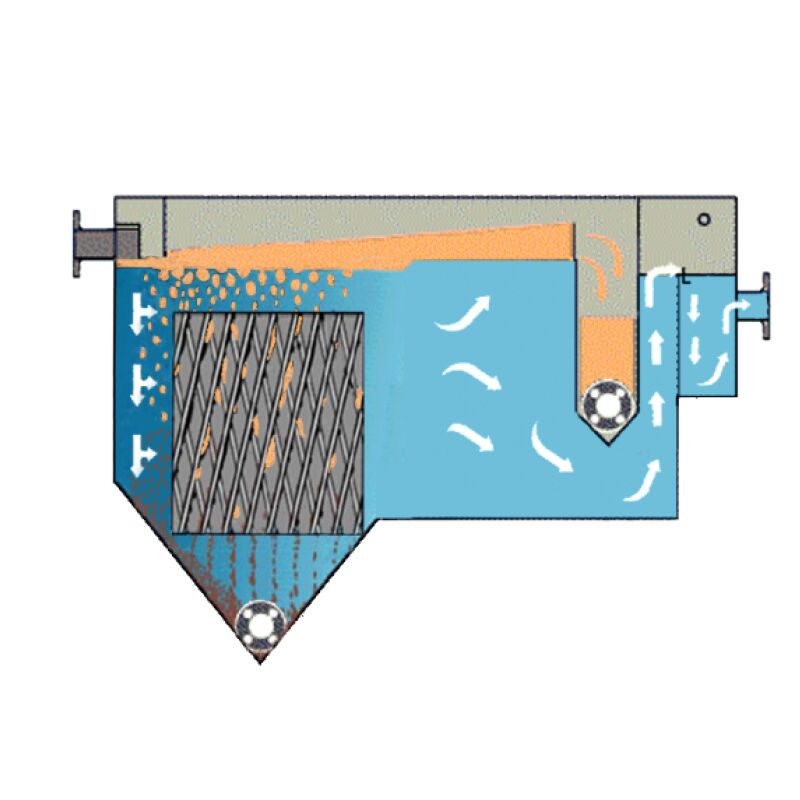

Clarifiers

KWI’s clarifier products range from our solids contact clarifier to our sedilamella. Each product is specialized for specific applications and can be readily incorporated as part of the design process. Our clarifiers offer reliable operation and easy installation. We can also upgrade existing clarifiers by installing Sedilamella and significantly increase sedimentation surface and system capacity.

Reverse Osmosis

KWI designs reverse osmosis processes to treat processed effluent and produce high quality reuse water. Reverse osmosis can effectively remove many organic and inorganic contaminants, pathogens and reduce salinity. Our RO process can be easily integrated and installed into any existing facilities.

Ceramic UF Membranes

KWI offers high quality ceramic UF membranes. The ceramic material offers a unique resistance to abrasive water. The water quality reached after UF treatment is excellent for water reuse.