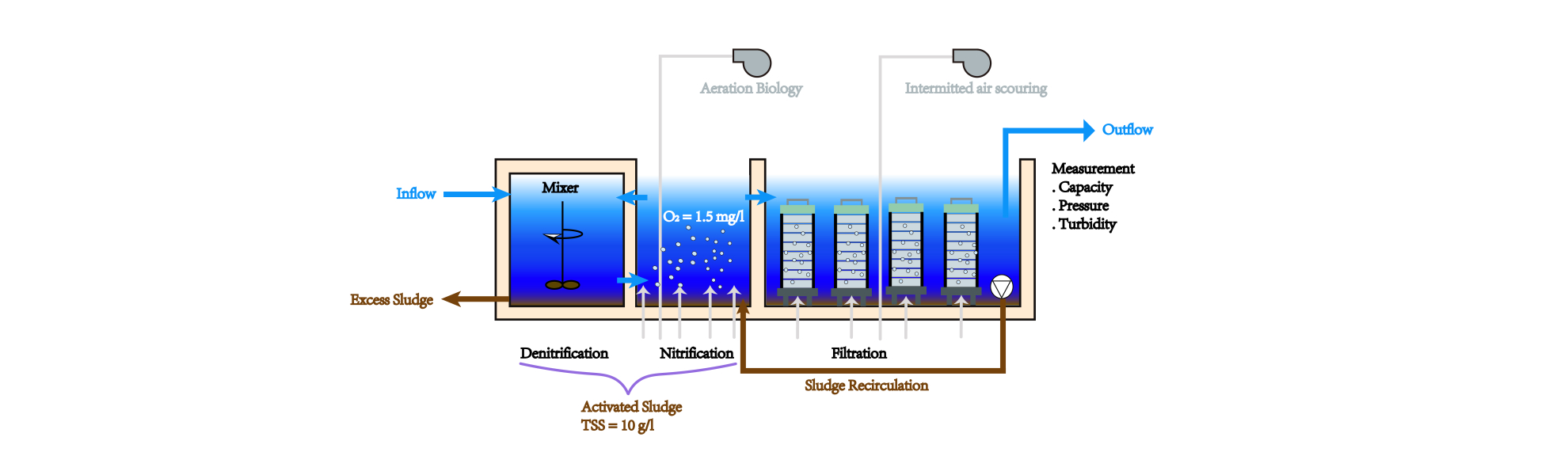

Key Features and Benefits

Treat nitrogen, phosphate with higher processing efficiency while producing less sludge

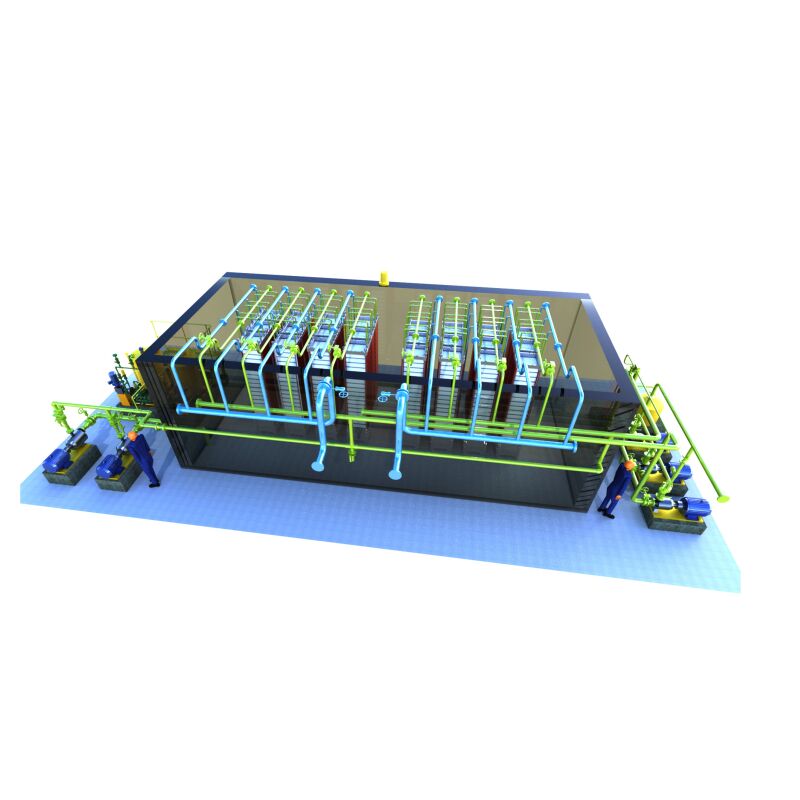

Small footprint, consistently high quality filtered water

Sludge production is only 30% of traditional process

Long life span (> 20 years)

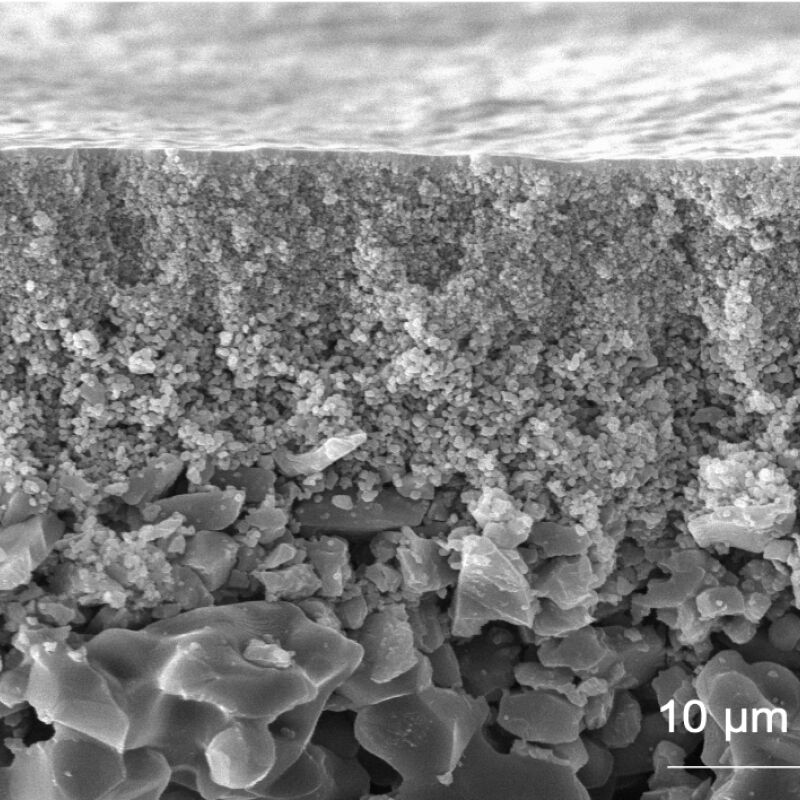

High flux rates (up to 35 LMH)

Lower operating costs due to lower backwash frequency and chemical consumption (less than 50%)

100% flux recovery with Chemical Enhanced Backwash after 10 years