DAF

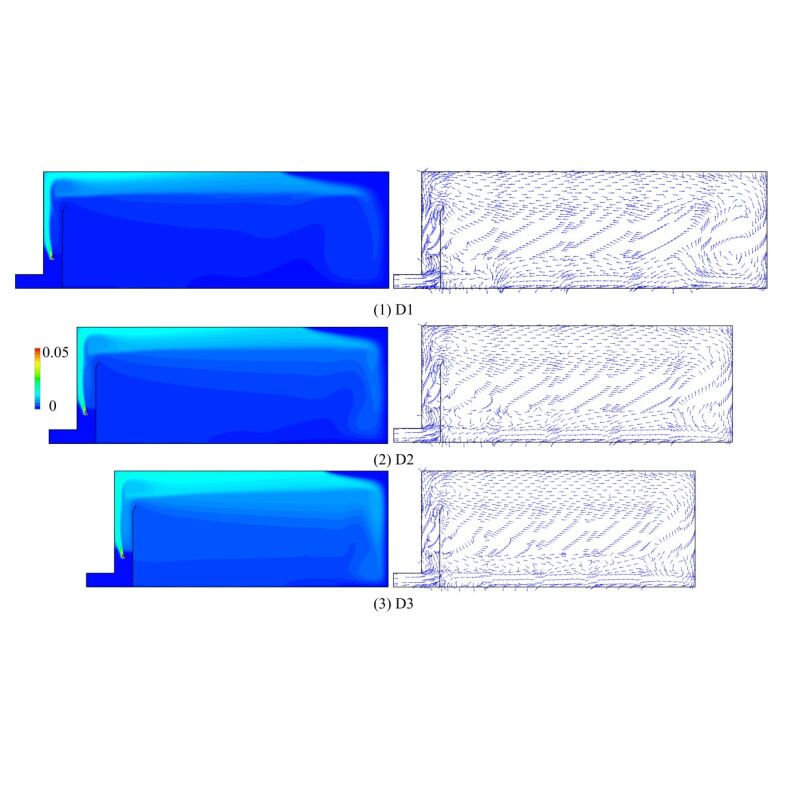

A comprehensive CFD analysis was carried out to address the design of our high rate DAF systems:

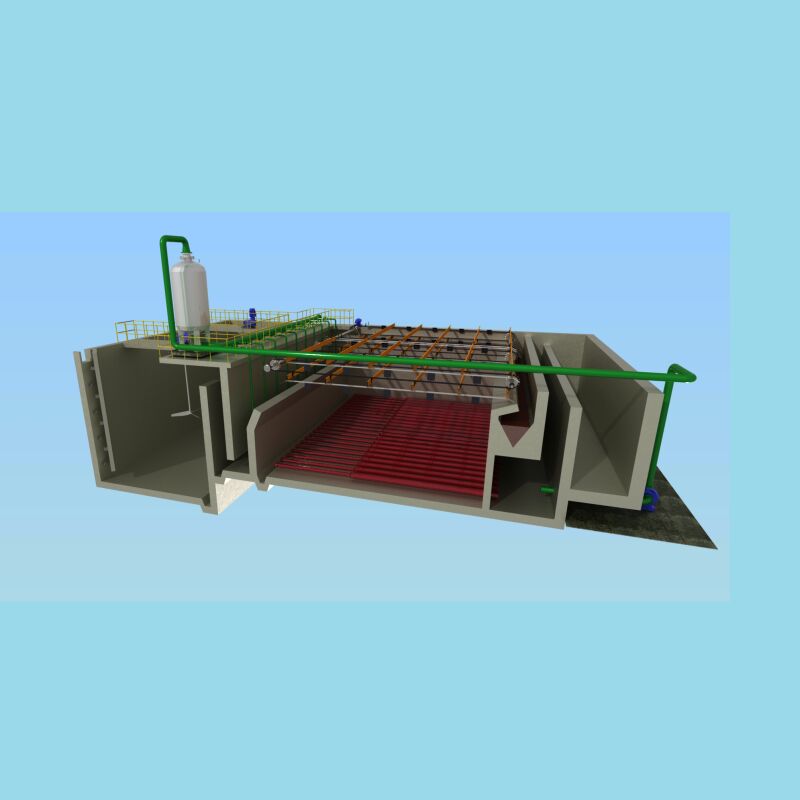

Inner floating mechanis

Flow pattern in the flotation tank

The length, height, baffle height and air inlet height of the DAF tank are chosen as optimization parameter.

Research Outcomes

Found optimized parameters to obtain both a good air distribution and flow distribution

DAF removal rate decreases as the DAF length decreases

DAF removal rate increases with the decrease of height

Removal rate of the DAF tank decreases as the baffle height decreases

DAF removal rate grows with the increase of the air inlet height