Key Features and Benefits

Stable effluent water quality

Long lifespan (more than 20 years)

Small footprint

Lower operating costs due to lower backwash requirements and chemical treatment (less than 50%)

Seawater filtration rack design: non-metallic parts and corrosion-free

Operation Parameters

Temperature 5-60°C

High flux 250-300 LMH

High recovery rate > 98%

Effluent Water Quality SDI < 2

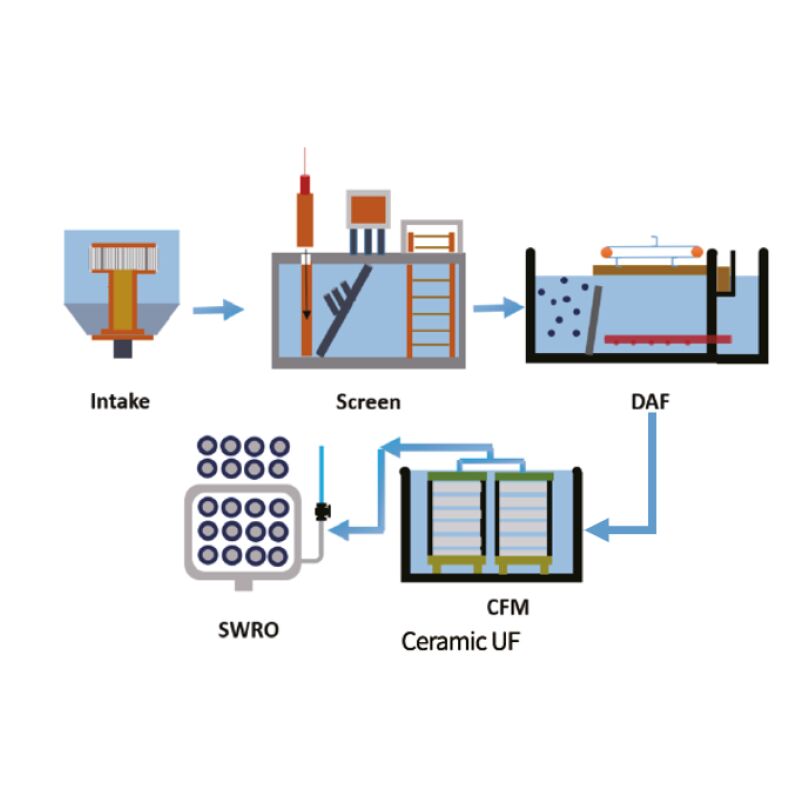

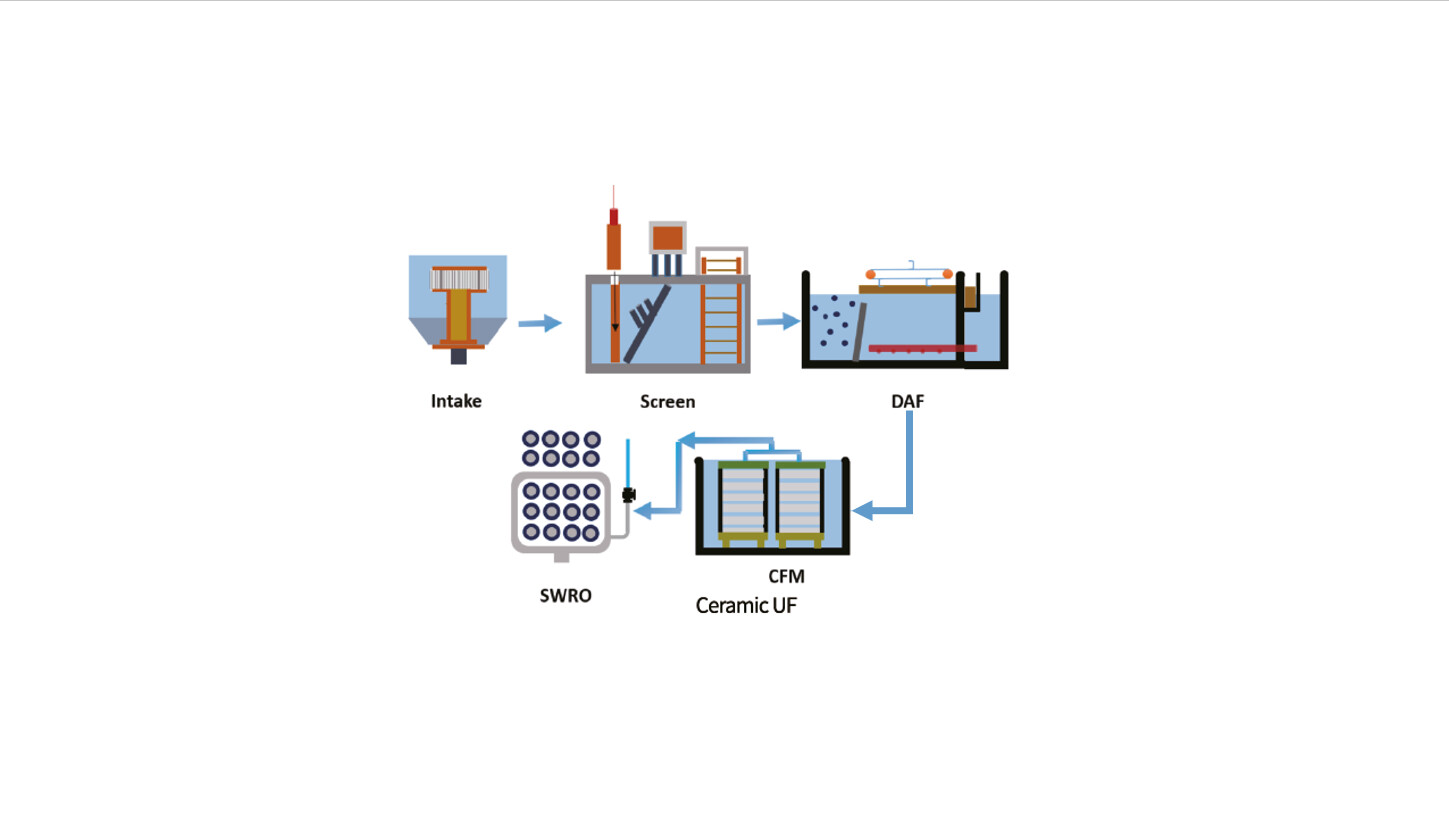

Best Combination: DAF

KWI dissolved air flotation is one of the most successful processes for handling both algae and suspended solids and combined with ceramic UF membranes will contribute to the reduction of organic materials being carried forward to the RO membranes. KWI has broad expertise in supplying both package and large DAF systems to desalination plants in the Middle East, South America and Asia.