KWI offers solutions ranging from pre-treatment technology such as process water re-use to process mine water treatment to remove pollutants and move towards zero liquid discharge.

We provide sustainable solutions and have long-term experience in increasing the efficiency of your water management. Our experience in heavy metal removal and treatment of contaminated water enables us to provide you with the most efficient and cost-effective solutions.

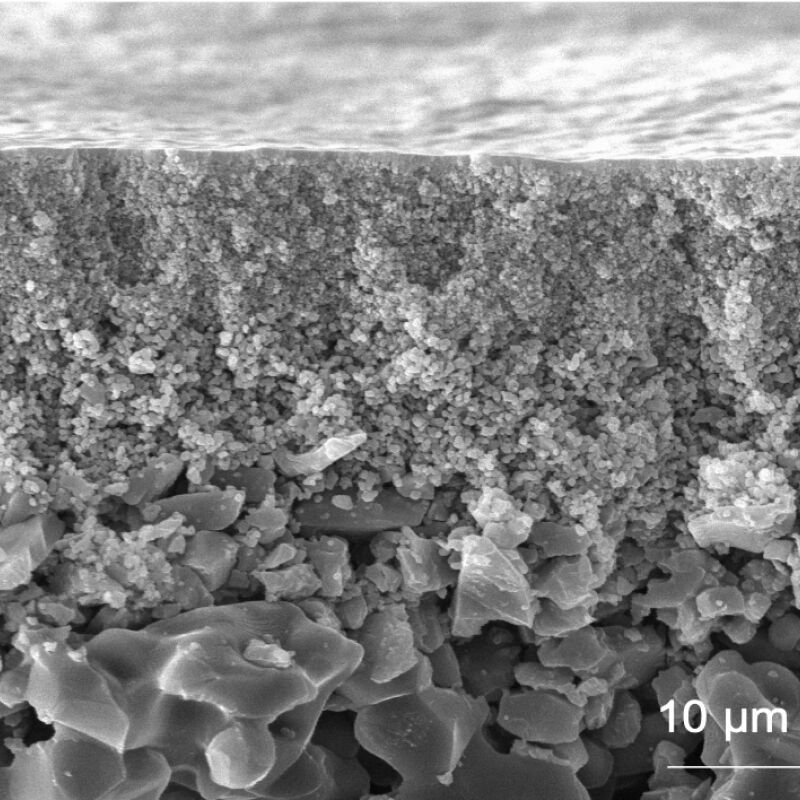

Ceramic UF Membrane

UF membranes are used to recycle and reuse water that contains virtually no physical solids. UF membranes produce a stable effluent quality, while maintaining water discharge standards according to legal requirements.

The implementation of this latest technology has helped mining companies to reduce costs, improve their processes and protect the natural environment of the communities in which they operate.

KEY FEATURES AND BENEFITS

High flux rates

Small footprint

Consistently high-quality filtered water

Long life span

No off-line cleaning

Lower operating cost due to lower backwash frequency and chemical consumption

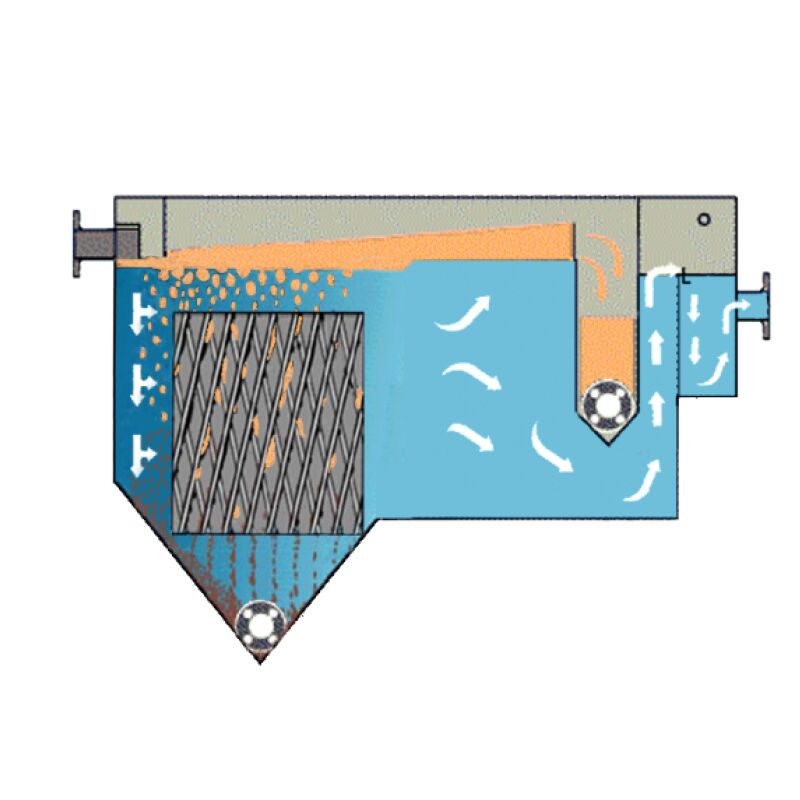

CPI

KWI CPIs are a cost-effective, high-rate solution used to separate and recover oil from water. The CPI takes up less space and are a more cost-effective alternative than the traditional API. At KWI we are precise with the design of our CPI products, to proactively accelerate the process of oil separation and recovery.

Nitrogen Dissolving Reactor (NDR)

Fast dissolving process: 10 – 20 s

No undissolved nitrogen losses at the outlet

High dissolved gas efficiency: up to 99%

Long-term stability, no auxiliary release device, no clogging caused by corrosion and scaling of the micropore releaser

DAF

Our DAF products can successfully remove and recover oil from these various applications delivers significant benefits to those in the steel industry.

DNF

The KWI DNF uses nitrogen instead of air to meet site requirements and is explosion-proof and seal-covered. Our DNF system can reduce oil, SS and COD from water with high mineralization, strong corrosivity, and over limit dissolved oxygen.

Reverse Osmosis

KWI designs reverse osmosis processes to treat processed effluent and produce high quality reuse water. Reverse osmosis can effectively remove many organic and inorganic contaminants, pathogens and reduce salinity. Our RO process can be easily integrated and installed into any existing facilities.