Enhanced Oil Recovery

We have decades of experience in developing technologies and solutions for the increasing demand of Enhanced Oil Recovery (EOR). We provide turn-key approaches for injection water, and for produced water treatment to enhance recovery, based on advanced technologies.

Sulfate removal package (SRP)

Seawater reverse osmosis (SWRO)

Dissolved Nitrogen Flotation (DNF)

Ceramic UF

Zero Liquid Discharge (ZLD)

Our proven technologies help end users reduce water consumption, maximize oil production, and comply with safety and environmental standards.

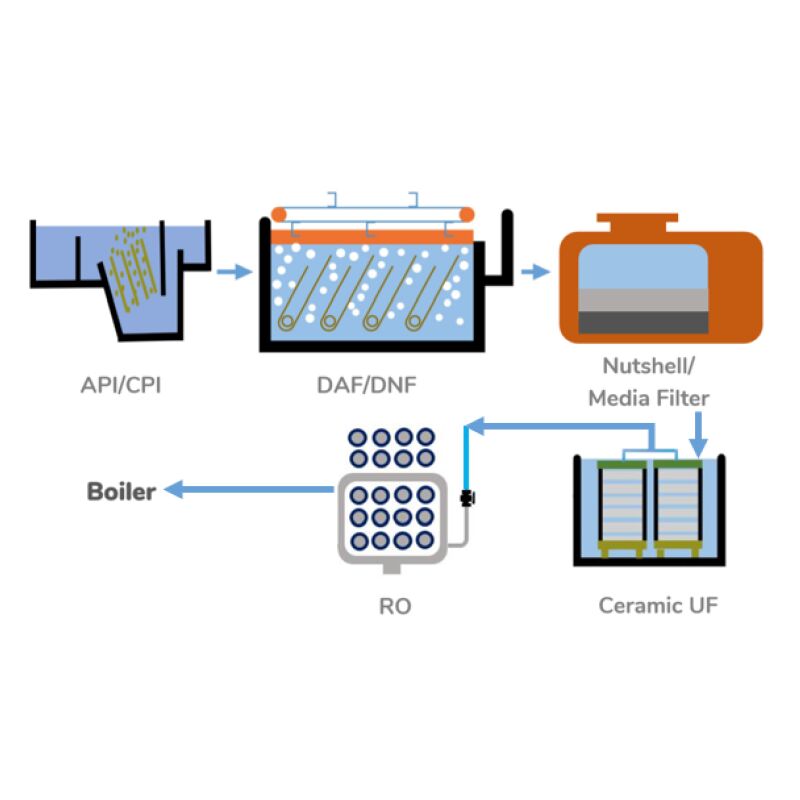

Process Flow from Produced Water to Boiler Makeup Water

In a Steam Flood Enhanced Oil Recovery (EOR) process, steam is injected into the wells, to lower the viscosity of oil for easy extraction. KWI offers proven and application technologies for the treatment of heavily contaminated produced water, generating purified water that can be reused for the production and injection of steam.

Our combined API & DNF oil/water separation technology provide superior performance in protecting the nutshell filter from significant contamination.

Produced Water Treatment

Produced water is one of the toughest waste streams for the oil and gas industry. With increasing volumes of produced water and a complex range of contaminants, one of the key challenges to meet ever stricter environmental regulations is to reduce high TSS and oil levels.

Corrugated Plate Inceptors (CPI)

API Separators

Dissolved Air Flotation (DAF)

Dissolved Nitrogen Flotation (DNF)

Nutshell/Media Filters

Ceramic Membrane Systems

Reverse Osmosis (RO)

Zero Liquid Discharge (ZLD)

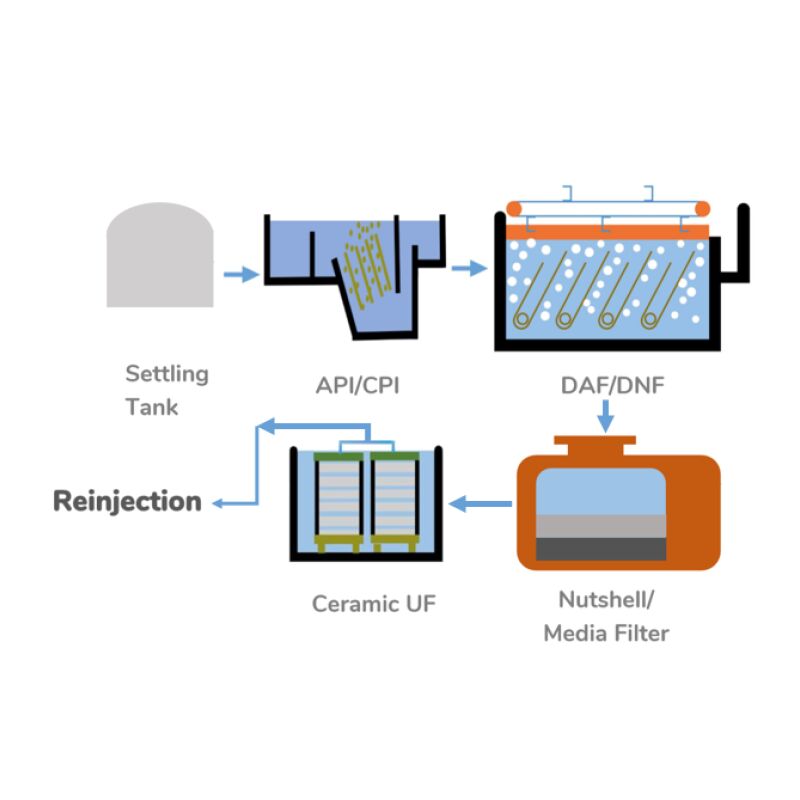

Process Flow for Produced Water

KWI DAF or DNF (dissolved nitrogen filtration) can sucessfully separate solids and liquids in produced water. DAF or DNF combined with cutting-edge ceramic UF membranes, which allows high quality filtration performance with extremely cost-effective economics for the oil and gas industry can effectively treat oily produced water.

DNF

The KWI DNF uses nitrogen instead of air to meet site requirements and is explosion-proof and seal-covered. Our DNF system can reduce oil, SS and COD from water with high mineralization, strong corrosivity, and over limit dissolved oxygen.

Oil and TSS removal efficiency: 95-99%

High hydraulic load: up to 30 m3/(m2·h)

High sludge load

High sludge concentration: >3% of solid content

Small footprint

Applicable for high temperature water treatment

Nitrogen Dissolving Reactor (NDR)

Fast dissolving process: 10 – 20 s

No undissolved nitrogen losses at the outlet

High dissolved gas efficiency: up to 99%

Long-term stability, no auxiliary release device, no clogging caused by corrosion and scaling of the micropore releaser

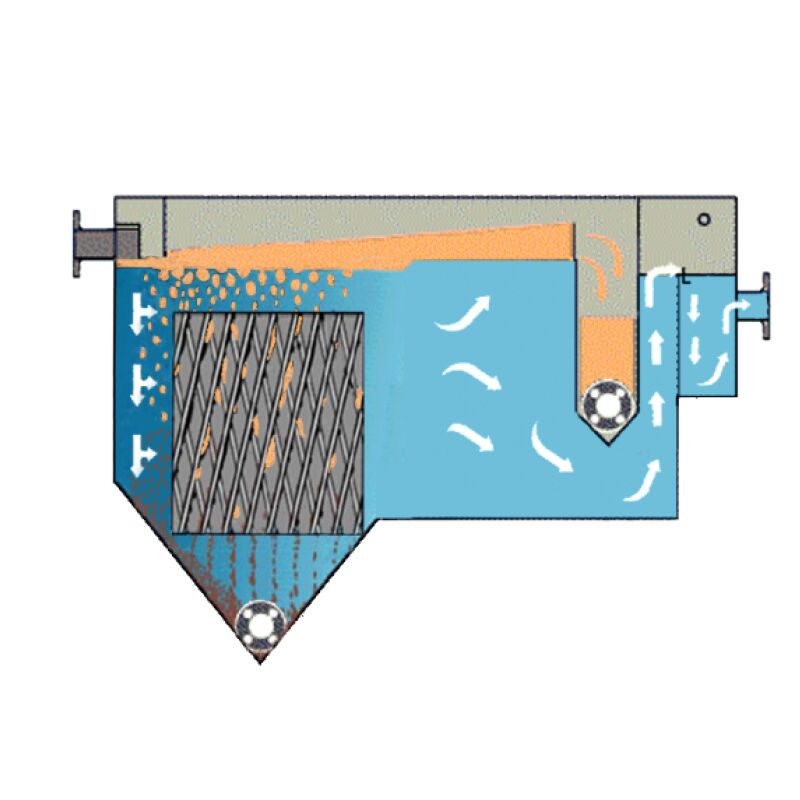

CPI

KWI CPIs are a cost-effective, high-rate solution used to separate and recover oil from water. The CPI takes up less space and are a more cost-effective alternative than the traditional API. At KWI we are precise with the design of our CPI products, to proactively accelerate the process of oil separation and recovery.

Megacell Series (Horizontal & Vertical)

The Megacell® Series is highly recommended for oil removal application based on their compactness, high removal efficiencies, low energy and chemical consumption. Combined with other physical-chemical treatment solutions, the Megacell series is perfect for oil removal applications.

Ceramic UF

Flexible membrane tower layout, stainless steel frame and piping, qualified for ATEX certifications

High recovery rate (more than 98%)

Long life span (more than 20 years)

Ceramic MBR

Lower backwash frequency and chemical consumption

Small footprint

High Flux rate (25-40 LMH)

Our Mission

Increase separation efficiency

Increase water quality

Lower your costs of production

Minimize environmental impacts

Ensure compliance with environmental regulations

Extend the life span of your plant