Pressure Filters

Our pressure filters are specially customized by our engineers. Our horizontal filters can be designed as a singular component or separate components. A water distribution structure is fitted on top of a water collection device.

Our pressure filters are installed in many large-scale engineering projects and guarantee a long performance life span. Combined with other pre-treatment technology, such as DAF, dual media pressure filter has been broadly used in the seawater desalination industry to remove suspended solids and silt.

Key Features and Benefits

Small footprint

Consistently high-quality filtered water

Lower construction costs

Simpler installation

Easy Operation

Reduce energy and operational costs

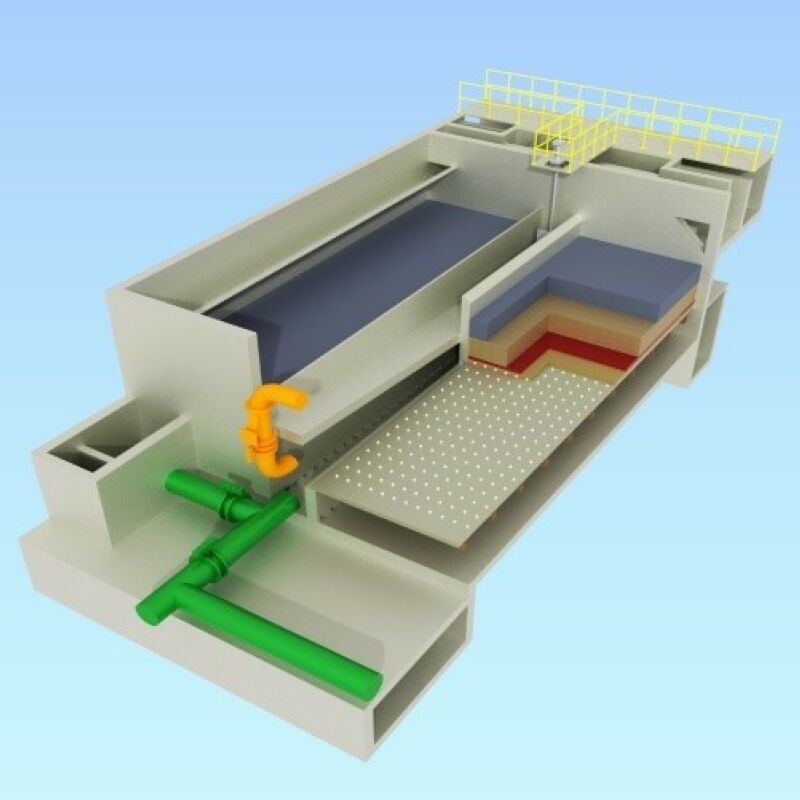

V-Type Filters

Granular media (conventional) filtration is the most commonly used seawater pre-treatment process for reverse osmosis (RO) desalination plants today.

This process includes source water filtration through several layers of granular media (e.g., anthracite coal, silica sand, garnet). Conventional filters used for saline water pre-treatment are typically rapid single-stage dual-media (anthracite and sand) units.

DMGF is a cyclical process that incorporates three sequential modes of operation:

Source water processing (filtration)

Filter media backwash

Maturation process

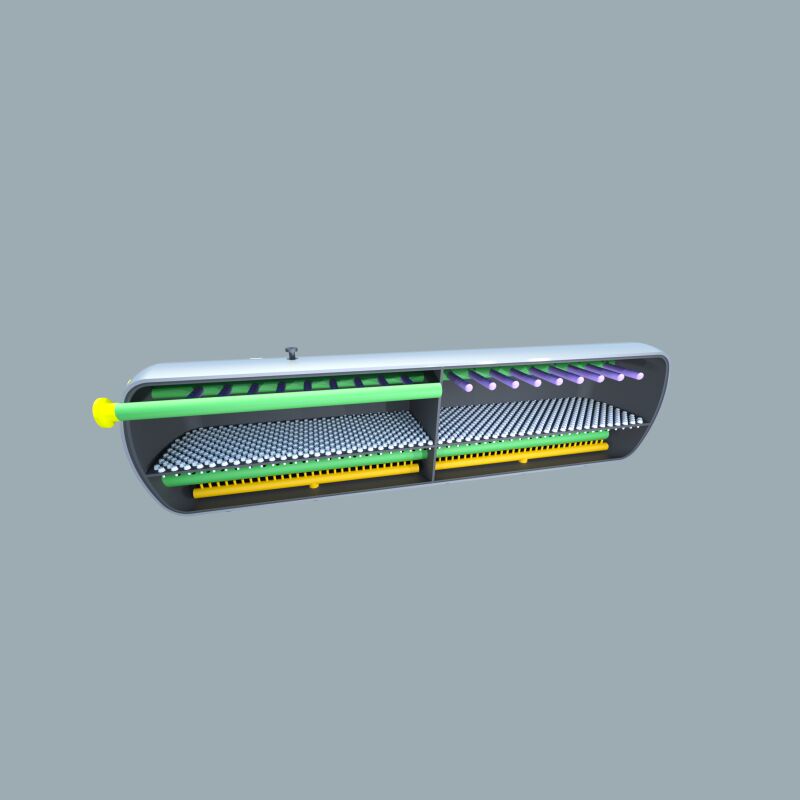

Variable Pore Filter

KWI’s variable pore filter is designed for percolation filtration, and it has advantages such as filter layer small resistance, high removal rate and high filtration velocity.

Our variable porosity filter has a positive flow deep bed filter designed with the theory of ‘coacervating’ and it is mainly characterized by using a combination of coarse and fine sand.

Key Features and Benefits

Higher hydraulic load, 18-21 m³/(m².h)

Better effluent water quality

Turbidity removal rate is up to 98%