Facing challenges of resource shortage, KWI fully devotes itself to environmental protection and sustainable development, by providing customized solutions and services for our municipal clients.

KWI supports municipalities to collect, manage and reuse sewage with our disruptive, massively scalable technologies.

With over 70 years of experience, our team has helped clients with consistent excellence to create sustainable solutions for water treatment and resource management.

Sewage Collection and Treatment

Water Reuse

Sludge Treatment

Engineering, Civil Works, Operation and Maintenance

We design our physical chemical treatment packages to significantly reduce the pollutant loads for our clients in the pharmaceutical and chemical industry.

KWI lamella clarifiers are an easy upgrade from existing, overloaded clarifiers with no room for expansion. Their key features include increased sedimentation surface and system capacity. We offer flexible mounting styles for different clarifier designs.

The KWI Sedilamella is ideal for upgrading existing overload clarifiers, which have no room for further expansion. KWI's solution combines the advantages of a parallel plate separator and a circular clarifier.

Effective phosphorus removal in municipal wastewater treatment (≤ 0.1 mg/L)

Can reduce the use of reagents by 10-20%

Oil and TSS removal efficiency: 95-99%

High phosphorus sludge concentration: up to 5% of solid content

Sludge can be dewatered directly

Combined with filtration for even higher efficiency

Suitable for revamping existing WWTPs

KWI offers high quality separation technologies including traditional sand filtration and ceramic UF membranes.

KWI is experienced in the design and manufacturing of medium- and large-scale horizontal dual media filters such as pressurised filters, V-type filters and variable pore filters to remove total suspended solids and silt before the reverse osmosis.

The KS Filter is equipped with a unique Double Sand Backwash device that allows flexibility and reliability with nonstop filtration during backwashing.

KWI offers high quality ceramic UF membranes. The ceramic material offers a unique resistance to abrasive water. The water quality reached after UF treatment is excellent for water reuse.

Biological treatments reduce the organic and nutrient content of the water with proven processes such as BAF, denitrification filters, and MBR equipped with ceramic membranes.

BAF combines biological oxidation and filtration together in one structure, eliminating the need for a secondary sedimentation.

Under anaerobic conditions, denitrification filters are widely used for TN removal as either secondary or tertiary treatment for plants to reach rising standards.

Deep Bed Denitrification Filter

Ceramic MBR can treat nitrogen, phosphate with higher processing efficiency while producing less sludge.

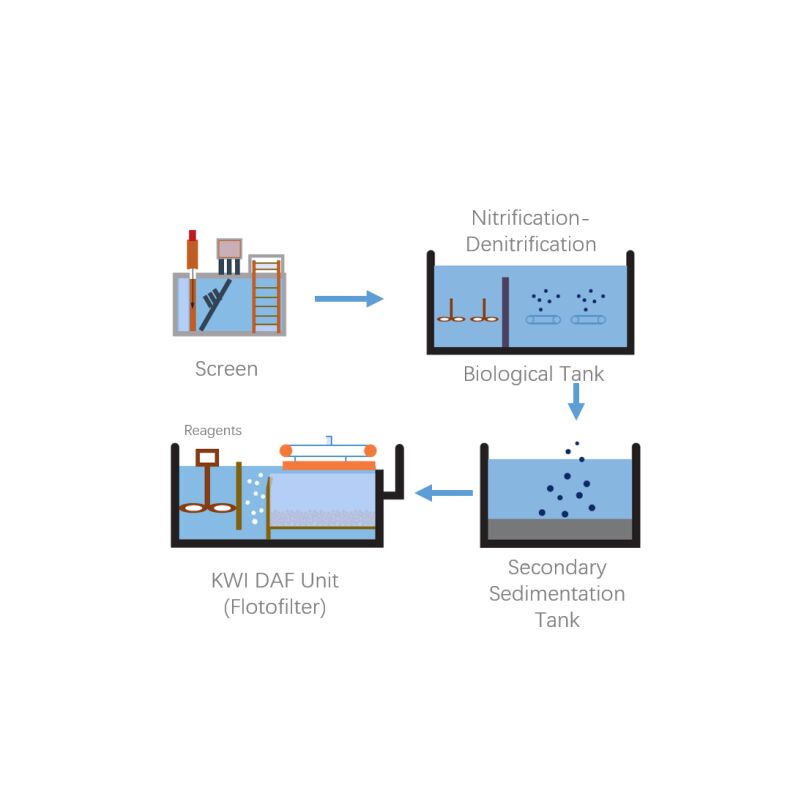

Moving Bed Biological Reactor process is a biological process where the biomass is developed on a moving carrier. The supports have a density close to the density of water and should offer the largest possible surface area. The process is usually combined with dissolved air floatation process for sludge clarification.

Increase the available quantity of dry volatile matter in a limited volume

Reduce the biological tank volume to 70 %

Improve biomass efficiency by creating a film instead of a traditional biomass bloc, in which a portion of the dry volatile matter is not available

Lower polymer consumption compared to Biofloat because the free biomass is around 1.5 to 2 g/l

Smaller flotation unit (based on hydraulic flow)

Avoid foam

Self-cleaning

KWI's well-crafted sludge management system offers DAF for sludge thickening and thin film dryers along with ancilliary equipment for both wet and dry sludge management. Our products are optimized to help clients reduce energy consumption and operational costs.

KWI manufactures DAF units specially designed for biological sludge thickening with high organic content.

The thin film dryer is a versatile patented technology that can achieve waste reduction and other resource requirements surrounding waste management.

KWI wet sludge management is designed for 60%-80% moisture level sludge and includes auxiliary equipment such as sludge silo, hydraulic sliding framework and wet sludge pumps.

KWI dry sludge management generally manages <60% moisture level sludge and includes auxiliary equipment such as Z-type bucket elevator, dry sludge silo, anti-cavitation sludge unloading device, and closed spiral for dry sludge transporatation.

Contact Us