Our Services

Reduction of the amount of water needed for the processes

Increased efficiency of water utilization

Reduction of costs and discharge fees

The textile and tannery industry faces wastewater characterized by high levels of pollutants including fat, oil, color and other chemicals. KWI provides cost-effective solutions to reduce fresh water usage by introducing closed water cycles, water reuse processes and wastewater treatment.

Reduction of the amount of water needed for the processes

Increased efficiency of water utilization

Reduction of costs and discharge fees

KWI manufactures DAF and clarifiers in stainless steel that guarantee an unbeatable lasting solution against wastewater.

Dissolved Air Flotation is considered to be very efficient and is widely used in treating the industrial process water in the textile industries and increase the water utilization in closed cycles. Our DAF units provide high clarification efficiency as a potential pretreatment for water reuse inside the factory.

KWI lamella clarifiers are an easy upgrade from existing, overloaded clarifiers with no room for expansion. Their key features include increased sedimentation surface and system capacity. We offer flexible mounting styles for different clarifier designs.

KWI offers high quality separation technologies including traditional sand filtration and ceramic UF membranes.

KWI is experienced in the design and manufacturing of medium- and large-scale horizontal dual media filters such as pressurised filters, V-type filters and variable pore filters to remove total suspended solids and silt before the reverse osmosis.

KWI offers high quality ceramic UF membranes. The ceramic material offers a unique resistance to abrasive water. The water quality reached after UF treatment is excellent for water reuse.

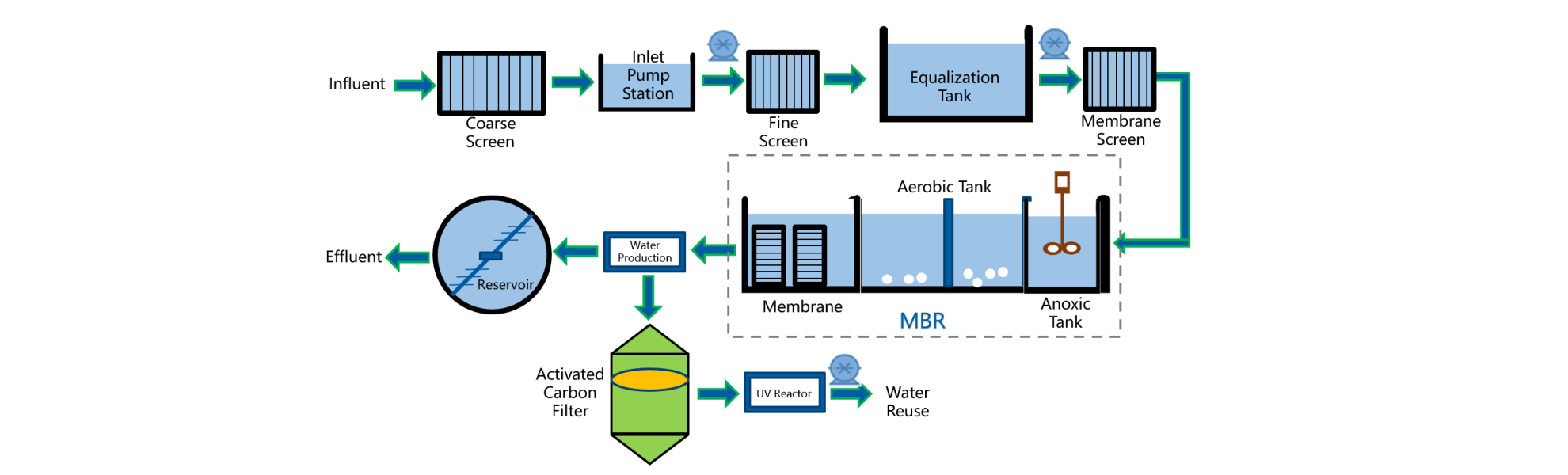

Biological treatments reduce the organic and nutrient content of the water with proven processes such as BAF, denitrification filters, and MBR equipped with ceramic membranes.

BAF combines biological oxidation and filtration together in one structure, eliminating the need for a secondary sedimentation.

Under anaerobic conditions, denitrification filters are widely used for TN removal as either secondary or tertiary treatment for plants to reach rising standards.

Deep Bed Denitrification Filter

Ceramic MBR can treat nitrogen, phosphate with higher processing efficiency while producing less sludge.

KWI's well-crafted sludge management system offers DAF for sludge thickening and thin film dryers along with ancilliary equipment for both wet and dry sludge management. Our products are optimized to help clients reduce energy consumption and operational costs.

KWI manufactures DAF units specially designed for biological sludge thickening with high organic content.

The thin film dryer is a versatile patented technology that can achieve waste reduction and other resource requirements surrounding waste management.

KWI wet sludge management is designed for 60%-80% moisture level sludge and includes auxiliary equipment such as sludge silo, hydraulic sliding framework and wet sludge pumps.

KWI dry sludge management generally manages <60% moisture level sludge and includes auxiliary equipment such as Z-type bucket elevator, dry sludge silo, anti-cavitation sludge unloading device, and closed spiral for dry sludge transporatation.

Contact Us