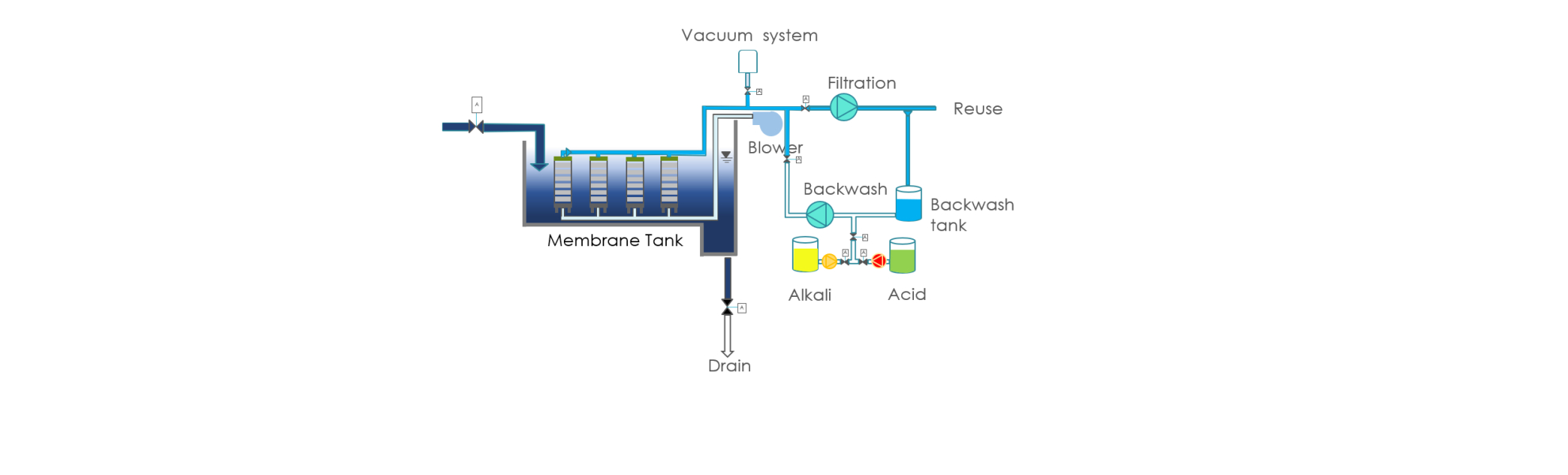

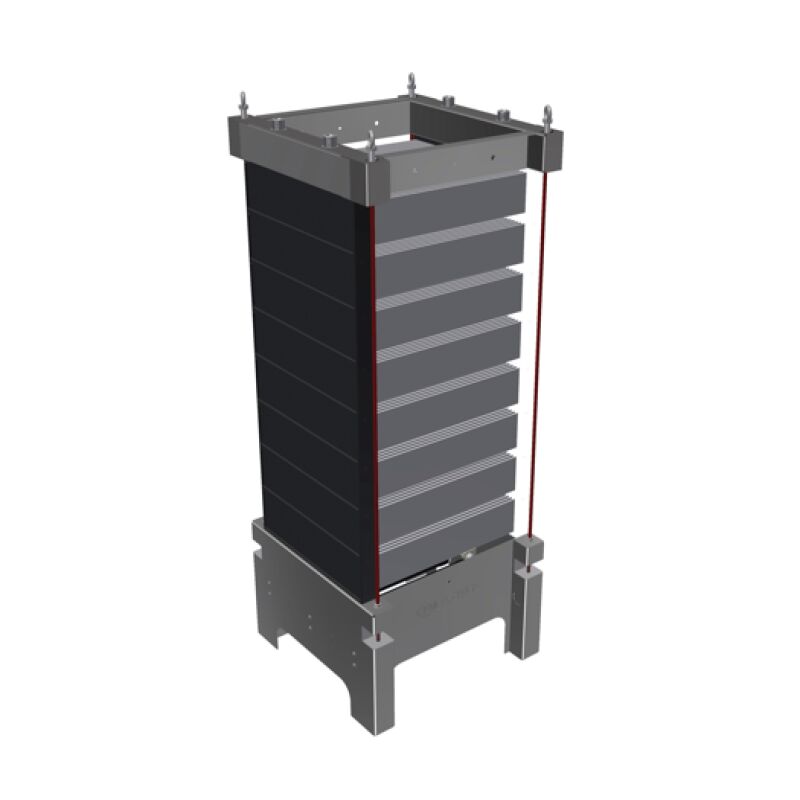

The advanced design allows unprecedented filtration performance with extremely cost-effective economics for different application fields.