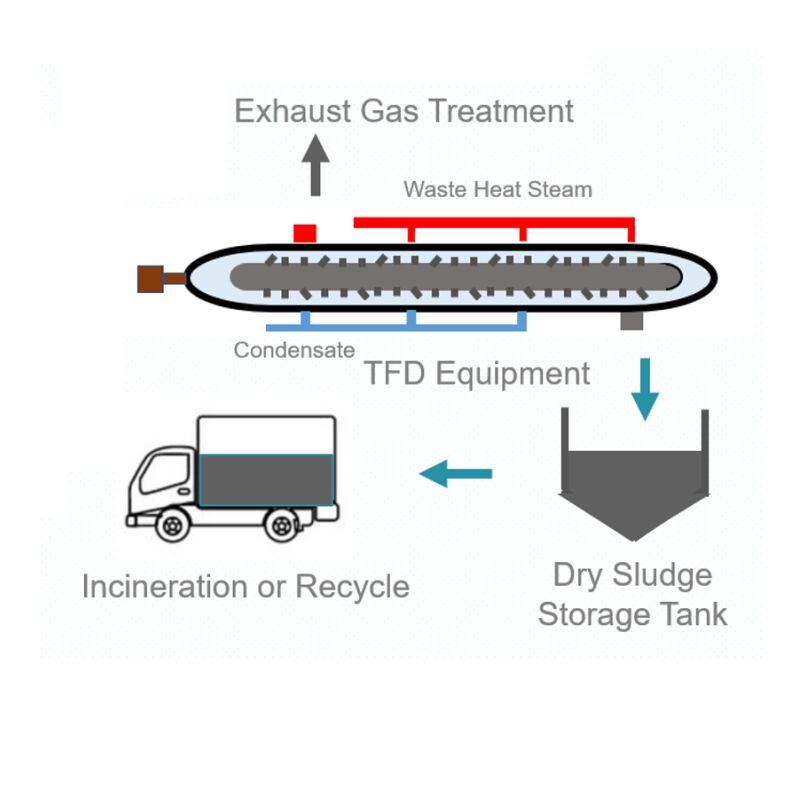

Dry Sludge Management

Dry sludge can help clients achieve energy conversion through incineration.

The steam and heat produced from the incineration process can be used for different applications or converted into electricity. Optimized sludge management can help reduce energy consumption and operational costs.

Dry Sludge Applications:

Mixed and burned with coal or household garbage

Burned separately

Fertilizer

Landfill

Auxiliary Equipment Dry Sludge Transportation

Closed Spiral

Horizontal transportation of dry sludge from TFD

Multiple sludge equipment can share one dry sludge transportation system

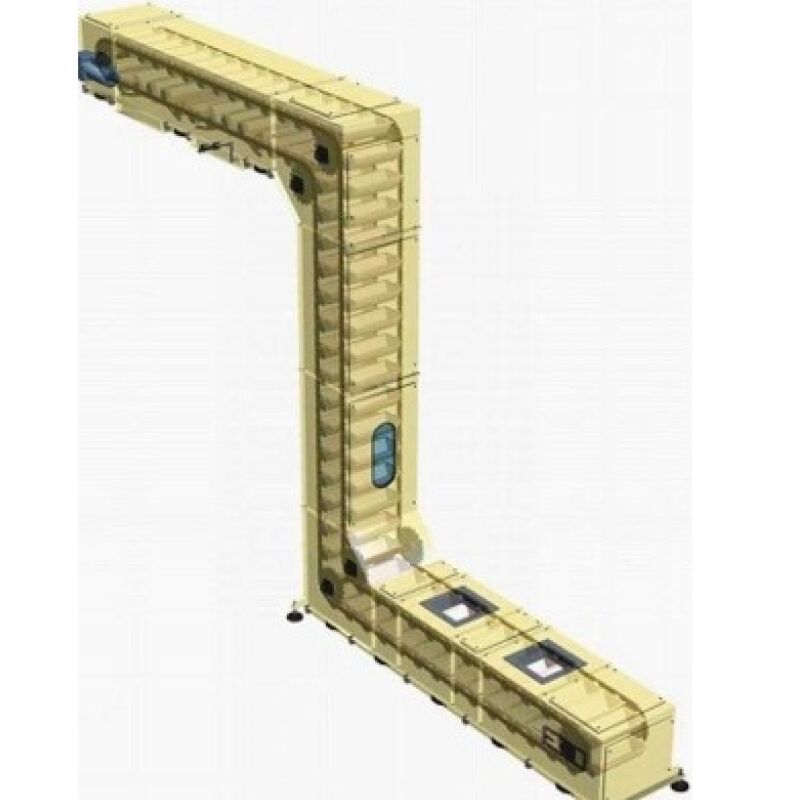

Auxiliary Equipment Dry Sludge Transportation

Z-type bucket elevator

Vertical transportation of dry sludge from the ground to the dry sludge storage tank

Multiple sludge equipment can share one dry sludge transportation system

Auxiliary Equipment Dry Sludge Silo & Mechanical Vibration Device

Mechanical Vibration Device

Installed at the bottom of the dry sludge silo

Vibration forces are transferred from the conical baffle to the dry sludge

Auxiliary baffle can prevent blockage at the tank outlet